Nanoporous atomically thin membranes for solvent waste recycling

Year

2023

Project team

Rohit Karnik with Aaron Persad, Lohyun Kim and Simar Mattewal

15 percent

of world’s energy consumption comes from separation processes

100 million tons

of carbon emissions could be reduced with membranes

Membranes

are limited in ability to handle challenging process streams

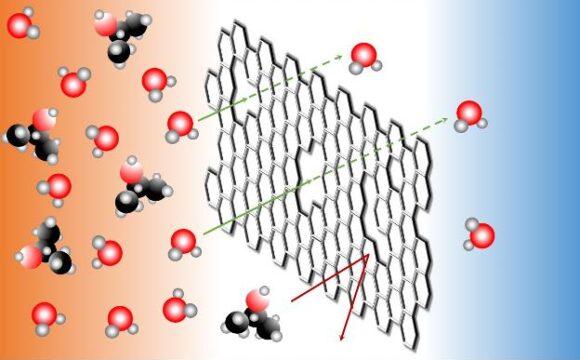

A versatile membrane for separating solvents

Many industries produce water-organic solvent mixtures that can be recycled but must be separated before reuse. Separation processes are costly and energy intensive, accounting for 15% of the world’s energy consumption, mostly through distillation and evaporation. The use of membranes in separation has the potential to reduce that consumption by 90%, saving 100 million tons in carbon emissions and $4 billion a year. However, existing membrane technology is limited in its chemical compatibility, versatility, and ability to separate liquids at the molecular level. This team is developing a nanoporous, atomically thin membrane for separating the most commonly used industrial solvents and overcome these challenges.